In today’s fast-paced industrial world, businesses can’t afford to compromise on material quality. Engineers, manufacturers, and project managers all look for materials that offer strength, durability, and versatility. Stainless steel plates meet all those expectations and more. But why are stainless steel plates essential in modern manufacturing? Let’s dive into the many reasons that make stainless steel plates a top choice across industries—and how we at Jianglin help meet that growing demand with custom solutions.

What Are Stainless Steel Plates?

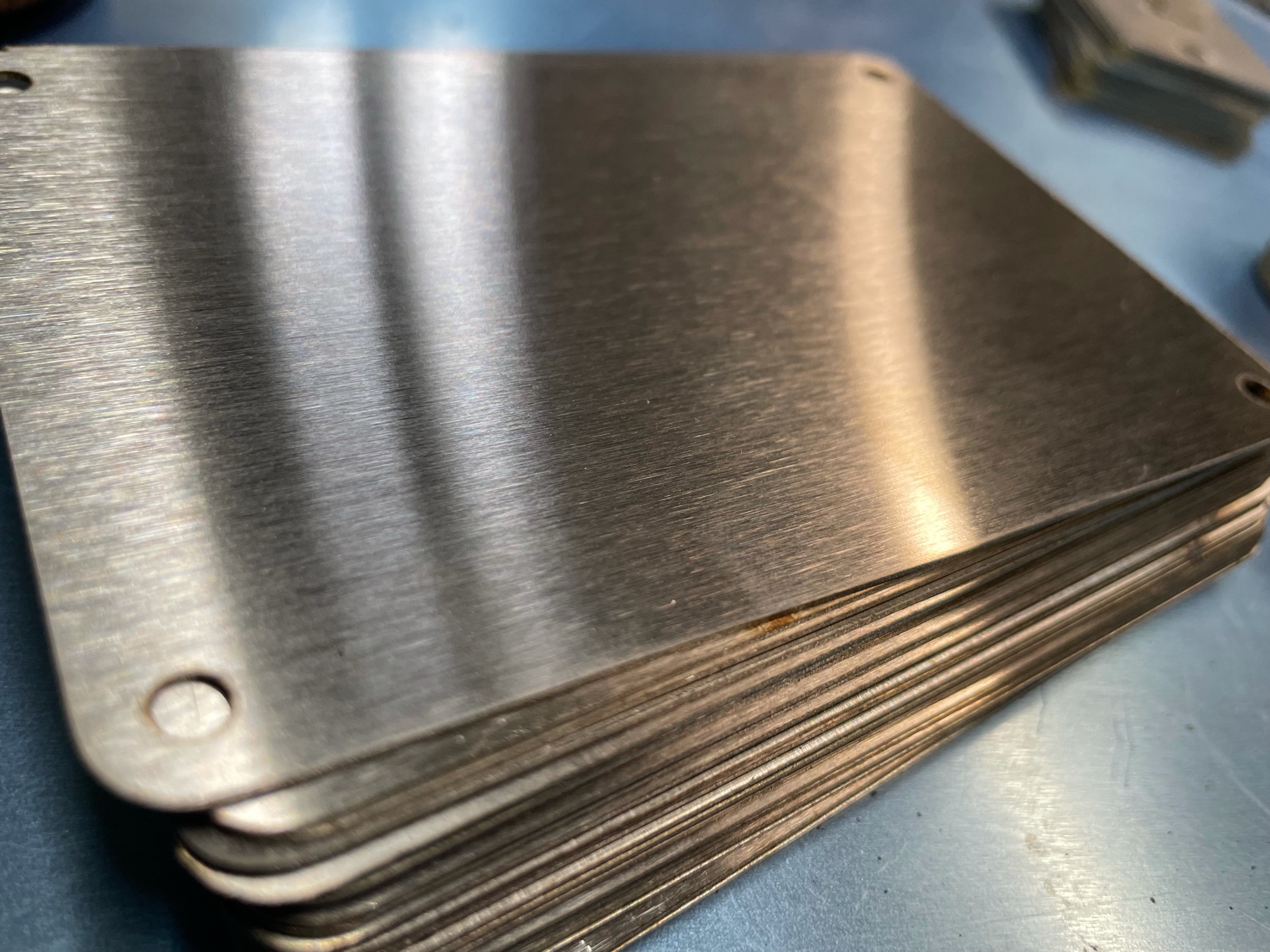

Before jumping into their uses, it’s important to understand what stainless steel plates are. These are flat steel products with a thickness typically above 6 mm. Manufacturers produce them by rolling steel into sheets and then treating them with chromium to improve corrosion resistance.

The result? A highly durable, rust-resistant material that performs in extreme conditions—whether it’s exposure to heat, chemicals, or moisture.

Why Do Industries Rely on Stainless Steel Plates?

You might wonder, “What makes stainless steel plates so reliable?” The answer lies in a combination of physical properties and cost-efficiency.

1. Corrosion Resistance

Stainless steel contains at least 10.5% chromium, which reacts with oxygen to form a passive layer on the surface. This layer prevents rust and corrosion even in harsh environments like marine or chemical industries.

2. High Strength and Toughness

Stainless steel plates handle extreme pressures and temperatures without bending, breaking, or cracking. That makes them ideal for construction, aerospace, automotive, and food processing equipment.

3. Hygiene and Cleanliness

In industries like pharmaceuticals and food manufacturing, cleanliness is crucial. Stainless steel’s smooth, non-porous surface makes cleaning easy and prevents bacterial growth.

4. Heat and Fire Resistance

Many grades of stainless steel can withstand high temperatures, making them suitable for boilers, ovens, and high-heat industrial processes.

Different Types of Stainless Steel Plates

Depending on the application, not all stainless steel plates work the same way. Let’s look at the most common types.

1. Austenitic Stainless Steel Plates

These plates offer excellent corrosion resistance and weldability. They’re non-magnetic and suitable for food equipment, architectural panels, and chemical containers.

2. Ferritic Stainless Steel Plates

Ferritic plates are magnetic and contain little or no nickel, which makes them more affordable. They work best in automotive trim and appliances.

3. Martensitic Stainless Steel Plates

These plates provide high strength and hardness. However, they offer slightly lower corrosion resistance. You’ll find them in cutlery, valves, and surgical instruments.

4. Duplex Stainless Steel Plates

Duplex plates combine the best features of austenitic and ferritic types. They provide high strength and corrosion resistance and are common in offshore oil rigs and bridges.

Common Applications of Stainless Steel Plates

Still not sure where stainless steel plates come into play? Let’s explore some key industries where these plates are indispensable.

1. Construction and Architecture

Skyscrapers, bridges, and even modern art installations use stainless steel plates. Their strength and aesthetic appeal make them perfect for both structural and decorative applications.

2. Automotive Industry

From car exhaust systems to decorative trims, manufacturers depend on stainless steel for its heat resistance and durability.

3. Food and Beverage Industry

Sanitation is non-negotiable here. Stainless steel plates are easy to clean and maintain, making them ideal for food preparation tables, storage units, and kitchen equipment.

4. Oil and Gas Sector

This industry often exposes equipment to extreme temperatures and corrosive chemicals. Stainless steel plates handle these conditions without failure.

5. Medical Equipment

Cleanliness and reliability are key. Stainless steel doesn’t harbor bacteria and holds up well to sterilization processes.

Why Choose Jianglin for Stainless Steel Plate Manufacturing?

At Jianglin, we don’t just sell stainless steel—we engineer solutions. As custom steel manufacturers, we focus on quality, precision, and reliability.

1. Customization Options

Every project has unique needs. We offer customized thicknesses, finishes, and grades tailored specifically to your industry and use-case.

2. Advanced Manufacturing Equipment

We use state-of-the-art machinery and quality control systems to ensure every plate meets global standards.

3. Fast Turnaround Times

Deadlines matter. Our streamlined production process and logistics network ensure timely deliveries without compromising quality.

4. Global Supply Chain

Whether you’re in North America, Europe, or Asia, we can deliver stainless steel plates quickly and affordably.

Comparing Stainless Steel Plates with Other Materials

Many materials promise strength and durability, but stainless steel often wins for several key reasons.

| Feature | Stainless Steel | Mild Steel | Aluminum |

| Corrosion Resistance | Excellent | Poor | Good |

| Strength | High | Moderate | Low |

| Cost | Moderate | Low | High |

| Lifespan | Very Long | Short | Moderate |

| Recyclability | 100% | 90% | 100% |

As the table shows, stainless steel plates offer the best all-around value when considering durability, maintenance, and long-term investment.

Tips for Choosing the Right Stainless Steel Plate

Not all stainless steel is created equal. To make the right decision, consider these factors:

1. Grade Requirements

Understand the specific grade (e.g., 304, 316, 430) needed for your application. Different grades offer different levels of corrosion resistance and mechanical strength.

2. Finish

Depending on your aesthetic or functional needs, choose a suitable finish—brushed, mirror, or matte.

3. Thickness

Thicker plates offer more strength but may be harder to work with. Balance durability with ease of fabrication.

4. Environment

Will the plates face chemicals, saltwater, or extreme temperatures? Always match the material properties with environmental demands.

Future Trends in Stainless Steel Plate Manufacturing

Technology evolves fast, and so does steel manufacturing. Here’s what the future holds:

1. Green Manufacturing

More companies, including Jianglin, now use eco-friendly production methods and recyclable materials to reduce their carbon footprint.

2. Smart Steel with Sensors

Imagine steel plates that monitor structural health! The future includes embedded sensors that detect cracks, heat, or stress.

3. Higher Grade Alloys

As demands increase, new stainless steel grades offer even better corrosion resistance and temperature tolerance.

Final Thoughts: Why Stainless Steel Plates Still Reign Supreme

When it comes to durability, versatility, and cost-effectiveness, stainless steel plates remain unbeatable. From skyscrapers to kitchen equipment, their applications are everywhere. They not only withstand time and stress but also look good doing it.

And when you need reliable, high-quality plates customized for your needs, Jianglin is your trusted partner. Our decades of expertise, cutting-edge technology, and client-first approach ensure you get exactly what your project demands.

So the next time you plan a manufacturing or construction project, don’t just ask, “What material should I use?” Instead, ask, “How can stainless steel plates from Jianglin make this better?”